Having a large variety of materials that can be engraved is one of the advantages of utilizing a laser engraver. The cost of laser engravers has traditionally been out of reach for most people, but the advent of low-cost versions and companies like The Engraving People has made it possible for anyone to benefit from them. You’ll need a powerful laser cutter to cut through the material. The top laser engraver, the finest material, and you’re good to go!

Which materials are best for laser engraving?

A laser engraver can be used to etch, cut, and mark a wide range of materials, including rubber, leather, polymers, textiles, wood, and metals. However, if you’re working with organic materials like wood or leather and utilizing a fiber laser engraver, keep in mind that the fiber laser beam at 1062 nm wavelength can render them translucent to the naked eye. Before you start utilizing your laser, obtain a list of permitted and prohibited items from the manufacturer.

Some of the most popular laser-etched materials:

- Glass

- Acrylic

- Metal

- Cardboard and paper

- Fabric

- Leather

- Marble and granite

- Stone and brick

- Wood

Marble and granite are both suitable for laser engraving.

If you want to make your photographs pop, consider engraving them on marble or granite. It’s a fantastic approach to make them stand out. Granite and marble have a beautiful contrast when etched, making them excellent choices for etching pictures. If you choose dark-colored marble or granite, there will be no need for color because the contrast between them will be strong. The white or dark grey image should emerge from the etching if it is properly done.

Laser engraving on bricks and stones

Bricks and stones are both great for writing on items that will be exposed to the weather, such as granite. They’re great for making mementos, engraving outdoor patio furniture, and other outdoor installations. Laser engraving is frequently employed as a donation method in parks, walkways, and colleges. Bricks bearing the names of contributors or sponsors may be inscribed and placed in monuments, parks, hospitals, zoos, religious structures, museums, and other settings. The engraved bricks are usually placed in a predetermined pattern.

Wood laser engraving

Wood is ideal for engraving since it may be carved and engraved with a wide range of materials, many laser cutting and laser engraving processes can create a variety of designs, and virtually any type of wood may be utilized. The most frequently engraved woods include the following.

- Chipboard

- Cork

- MDF

- HDF

- Veneers

- Precious woods

- Multiplex

- Natural wood, real wood

- Solid wood, solid timber

- Plywood

Prototyping, inlays, and bespoke products are just a few of the many types of wood laser applications. With the appropriate laser engraver and wood, you can create any shape or motif imaginable.

Glass laser engraved

To generate stunning outcomes, almost all glass goods may be laser engraved. Engravings may be used to make mugs, vases, wine bottles, and wine glasses more unique. The majority of well-known wineries and distillers, in fact, laser etch their logos on their bottles.

Laser engraving on Acrylic

Acrylic sheets, sometimes known as polymethyl methacrylate (PMMA), are long-lasting and lightweight. They’re a fantastic choice for replacing glass. The most common type of PMMA is called poly(methyl methacrylate) cast and extruded, which can be formed in two ways: cast or extruded. These two types of acrylic react differently to laser engraving. The frosty white appearance of cast PMMA provides a wonderful contrast against its transparent material. Acrylic produced by extrusion, on the other hand, is transparent and does not provide a large contrast. Extruded acrylic is therefore most suited to do a laser cutting project, while cast acrylic would be ideal for all other laser engraving tasks.

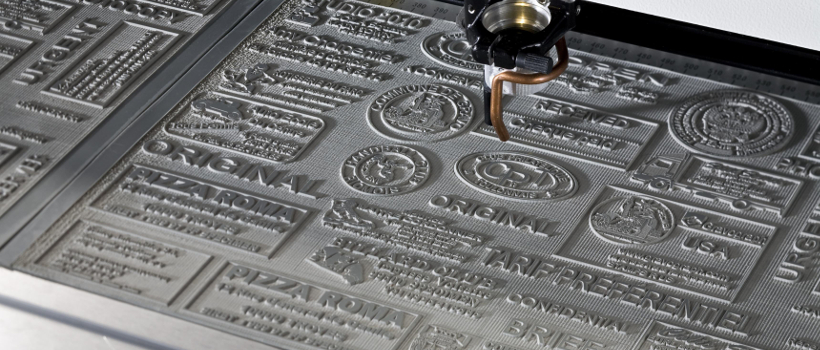

Metal engraving with a laser

The majority of metals can be laser etched, however the following are some of the most frequently etched materials:

- Aluminum

- Brass

- Silver

- Gold

- Palladium

- Titanium

- Platinum

- Carbides

- Coated metals

- Steel

- Copper

- Iron

- Stainless steel

In the world, laser engraving and laser cutting are two popular materials. For example, the creation of art, aircraft wing modifications to enhance aerodynamics, automobile component manufacturing, chop and part engraving are just a few examples. Metal laser engraving can be divided into two categories: industrial laser engraving and promotional laser engraving.

With metal, you may produce a variety of promotional items for your home-based laser engraving business. Let’s have a look at some metal items that you may personalize for your clients.

- Hip flasks

- Thermos flasks

- Lighters

- Bottle openers

- Laptops, tablets, and mobile phones

- Cutlery

- Jewelry

- Pocket knives

- Key fobs

- Cardboard and paper

- Picture frames

- Door signs

- Locks

- Nameplates

From basic greeting cards to bespoke book covers, there are an infinite number of designs for laser engraved cardboard and paper items. The following are some of the best materials for laser engraving:

- Cardboard

- Corrugated cardboard

- Art paper

- Fine paper

Fabric with laser engraving

Many different materials may be laser inscribed, including natural and manufactured textiles. The most frequently laser engraved materials are cotton and microfiber. Microfiber is produced from polyamide fibers. Polyamide is a polyamides (nylon) that is chemically synthesized from petrochemical raw materials.

Microfiber cloths are extremely long-lasting, which is why they’re so popular for laser engraving. The use of a tight weave in 100% cotton fabric may create gorgeous engraving. Cotton is not a recommended material for printing because loose threads will not provide a satisfactory result.

Laser engraving leather

Leather goods are always in high demand, and laser engraving is the greatest method to personalize a leather item. Leather goods of almost any sort, including nubuck and suede, may be laser etched. There are a number of different techniques to engrave leather. The most typical techniques are burnishing and carving. Here is a rundown of the many forms of etched leather available.

- Alcantra leather

- Napped leather

- Natural leather

- Suede leather

- Nubuck leather

- Synthetic leather

Synthetic leather, also known as manufactured leather, may be laser inscribed. When it comes to laser etching real leather, the most important thing is the hue. In general, dark or black leather should not be etched. On lighter leather, engraved designs will stand out more dramatically.

Because of their common use, leather goods may be inscribed. Here are a few samples:

- Crafts

- Briefcases

- Office products

- Promotional materials

- Purses

- Wallets

- Bracelets

- Belts

Because leather is a highly durable and difficult to mark material, laser engraving is perfect for it.

Last but not least

To summarize, there is no such thing as the ideal material for laser engraving. The finest material will be selected based on the requirements outlined above. Before you buy a laser engraver, figure out what sort of material you want to engrave. Some materials, on the other hand, react better to cutting than engraving and therefore perform better with engravers that have been developed especially for them. Laser beams are far more potent than those used on wood. The hardness of the materials that make up your finished product influences the energy required to penetrate them. The laser beam strength required varies based on the material. Once you’ve decided on your material, you may select a laser engraver that is appropriate for you.